PLASMA SYSTEMS

The next generation XPR™ plasma cutting systems by Hypertherm represent the most significant advance in mechanized plasma cutting technology. Offering unmatched X-Definition™ cut quality on mild steel, stainless steel and aluminum, the XPR increases cut speed, dramatically improves productivity and slashes operating costs.

Features

Specifications

Features

- Consistent ISO range 2 results on thin mild steel

- Extended ISO range 3 cut quality results compared with earlier plasma technology

- Superior stainless steel cut quality across all thickness ranges

- Superior results on aluminum using Vented Water Injection™ (VWI)

Industry-leading Cut Quality

The XPR advances HyDefinition® cut quality by blending new technology with refined processes for next generation, X-Definition™ cutting on mild steel, stainless steel and aluminum.

Engineered System Optimization

XPR is engineered to deliver the highest quality cuts and optimal system performance automatically.

Advanced power supply technology delivers highly responsive, rapid system feedback, and automatically intervenes to eliminate events that negatively impact system efficiency and consumable life.

XPR's Arc response technology™ provides automatic torch and ramp-down error protection. Sensors in the power supply deliver refined diagnostic codes and significantly enhanced system monitoring information that reduces troubleshooting time and provides proactive system maintenance data for improved system optimization.

- Significantly reduced operating costs than previous generation technology

- Increased cut speeds on thicker materials

- Dramatic improvement in consumable life on mild steel applications

- Thicker piercing capability than competitive plasma systems

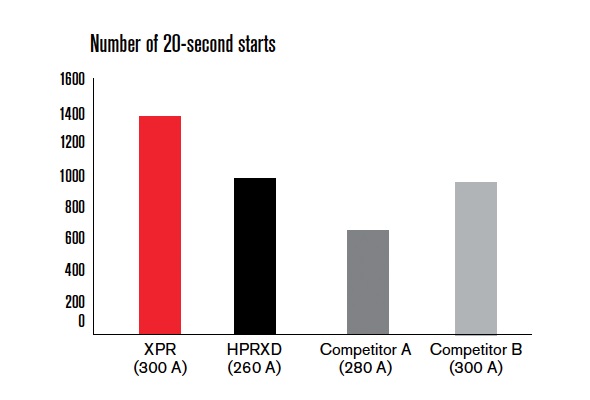

- Increased consumable life 3 times that of competitors' systems by eliminating the impact of ramp down errors

- Reduced the impact of catastrophic electrode blowouts which can damage the torch at high current levels

Optimized Productivity

- Intuitive operation and automatic monitoring redefine ease of use

- Full control of all functions and settings via the CNC

- Automatic system monitoring and specific troubleshooting codes for improved maintenance and service prompts

- EasyConnect™ torch lead and one hand torch-to-receptacle connection for fast and easy change-outs

- QuickLock™ electrode for easy consumable replacement

- WiFi in power supply can connect to mobile devices and LAN for multiple system monitoring and service

Ease of use

Advanced Process Control

Three console options – Core™, Vented Water Injection™ (VWI) and OptiMix™ – offer unmatched mild steel cut quality with each console delivering successively enhanced cutting capabilities on stainless steel and aluminum. All consoles can be fully controlled through the CNC for high productivity and ease of use.

Gas Console Gases & Fluids

| Core | Vented Water Injection (VWI) | OptiMix | |

| O2/N2/Air | X | X | X |

| F5/Ar/h3O | X | X | |

| h3-N2-Ar Mixing | X |

Specifications

Click below to view the product

brochure for the XPR Plasma System.

Interested in the XPR Plasma System?

We are happy to answer any questions you may have or provide you with an estimate.