PLASMA CUTTING TABLES

Veracity CNC plasma cutting tables are robust, durable, and efficient for controlling smoke and fumes from the plasma cutting process. Veracity offers a wide range of cutting tables in various sizes to fit your cutting needs. Water tables feature an adjustable water level that can be raised to submerge plate for underwater plasma cutting and lowered for easier retrieval of parts after cutting. Downdraft air tables can be zoned with manual lever or automated cylinder control to provide full table coverage for optimal capture and disposal of smoke and dust particles.

Features

Specifications

Features

Water Table

Downdraft Table

Controlling smoke and fumes is critical while plasma cutting. When using a CNC cutting table you have two choices: water or downdraft. Each has pros and cons that should be considered when choosing between the two.

- Less expensive to purchase and operate

- Water reduces heat warpage on thin plate and keeps parts cool enough to remove immediately

- Supresses noise and high intensity arc flash

- Adjustable water level provides ability to submerge plate for underwater plasma cutting

Water Table Advantages

- Easier to maintain with almost no adjustment needed once system is in operation

- Produces cleaner parts with no water contamination

- Provides a cleaner work environment and fully contains dangerous fumes that can pose health risks to workers

Downdraft Table Advantages

- Water in unheated shops or cold areas can freeze

- Machine components, table, slats, and steel plate are susceptible to rust

- Difficult to clean and dispose of contaminated water

- Aluminum alloys react with water and produce hydrogen gas which may cause dangerous explosions

Water Table Disadvantages

- Requires purchase of an extractor system and filters

- Requires ample space to install ductwork in shop and extractor system outside

- Blowers used to collect fumes will suck out the air in your shop which makes climate control difficult

Downdraft Table Disadvantages

- Veracity dust collectors for downdraft tables extract dust and fumes and provide a cleaner work environment

- Removable slag pans to reduce cleanup time and protect table surfaces from direct contact with slag and debris

- Plasma Quench, an anti-rust and anti-bacterial additive designed to reduce corrosion and microbes that cause damage and odor

Additional Options

Specifications

Click below to view the product

brochure for our plasma cutting tables.

Interested in our plasma cutting tables?

We are happy to answer any questions you may have or provide you with an estimate.

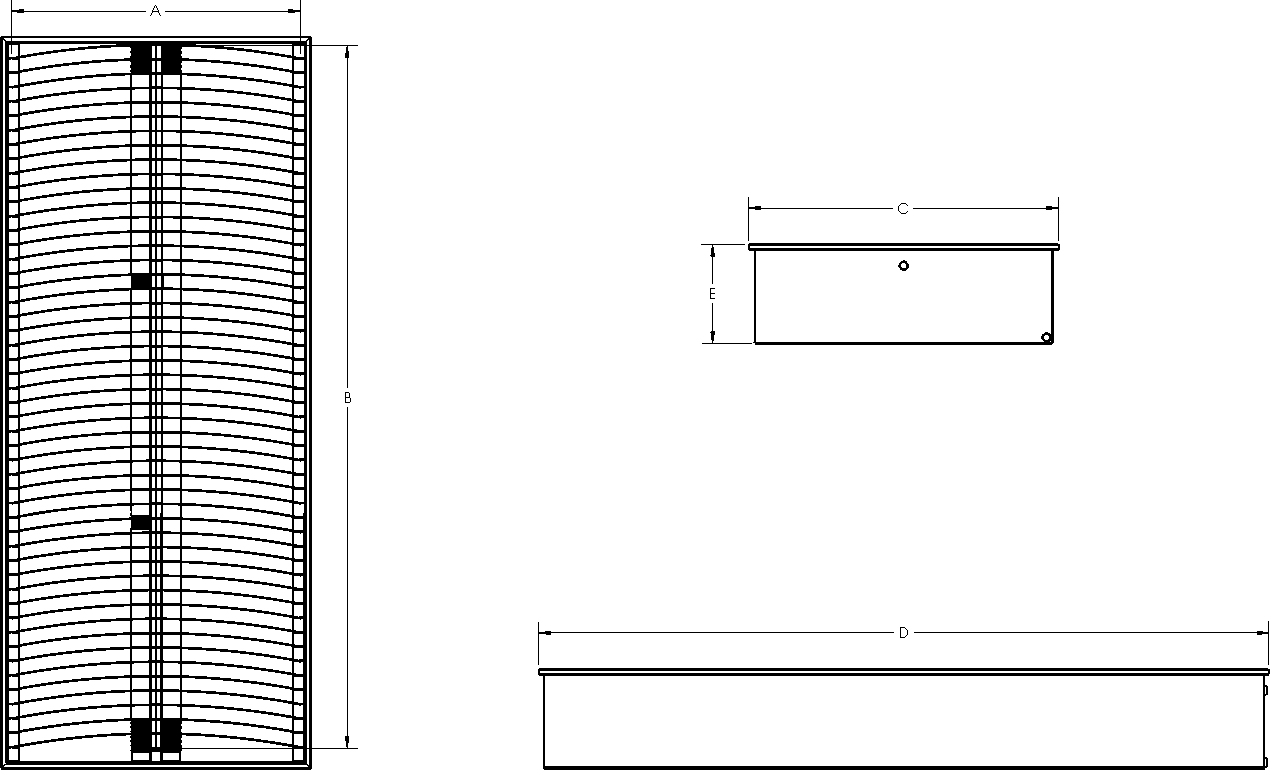

| Table Size | 4 ft | 5 ft | 6 ft | 8 ft | 10 ft | 12 ft | 14 ft | 16 ft |

|---|---|---|---|---|---|---|---|---|

| Nominal Cut Width (A) | 54" | 66" | 78" | 102" | 126" | 150" | 174" | 198" |

| Nominal Cut Length (B) | 108" minimum (expandable in 48" increments) | |||||||

| Overall Width (C) | 58" | 70" | 82" | 106" | 130" | 154" | 178" | 202" |

| Overall Length (D) | [Nominal Cut Length] + 4" | |||||||

| Overall Height (E) | 26" | |||||||

Custom sizes are available at request